Mizar Weekly | Electrostatic Separation in Recycling: The Key to Higher Purity

Electrostatic separation is one of the most effective technologies for sorting fine mixed materials in the recycling industry. By utilizing the difference in electrical conductivity between various materials, electrostatic separators enable recyclers to achieve high-purity results—especially when processing complex mixtures such as cable granules, shredded electronics (WEEE), and plastic-metal compounds.

What Is Electrostatic Separation?

Electrostatic separation is a dry technology that separates materials based on their electrical properties. When subjected to a high-voltage field, conductive materials like copper or aluminum lose their charge quickly and fall off, while non-conductive materials like plastics cling longer to the electrode. This allows efficient separation without water or chemicals—making it both cost-effective and environmentally friendly.

Where Is It Used?

This technology is widely applied in:

Cable recycling lines, to separate fine copper from plastic after granulation.

E-waste recycling, for recovering precious metals from PCB particles.

Plastic recycling, to cleanly sort polymers from metal contamination.

Why Is It Important?

Achieving a metal purity of over 99% is critical in the recycling business. Buyers demand cleaner fractions, and governments require compliance with waste separation standards. Electrostatic separators help achieve:

Higher market value of end-products

Reduced material loss

Compliance with environmental regulations

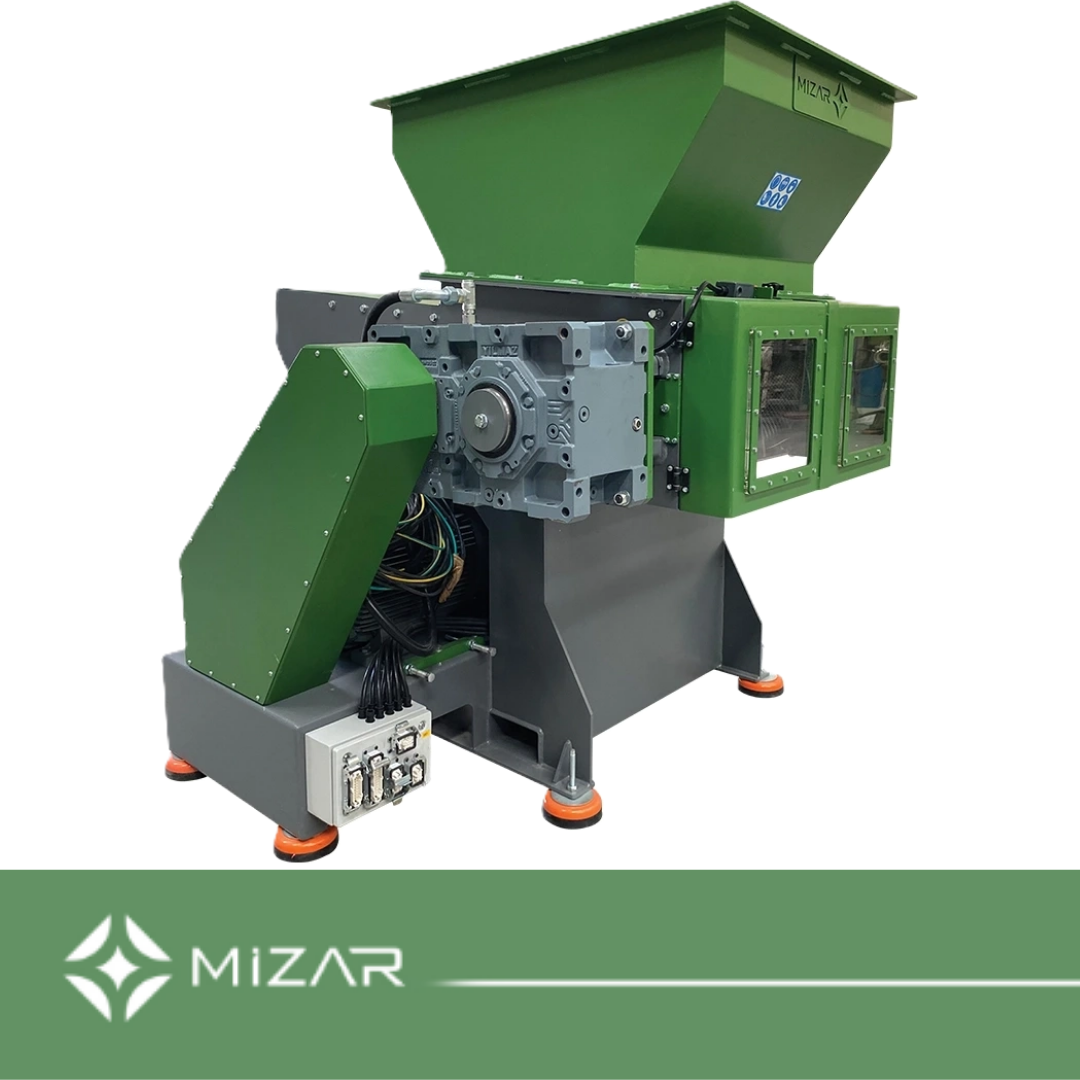

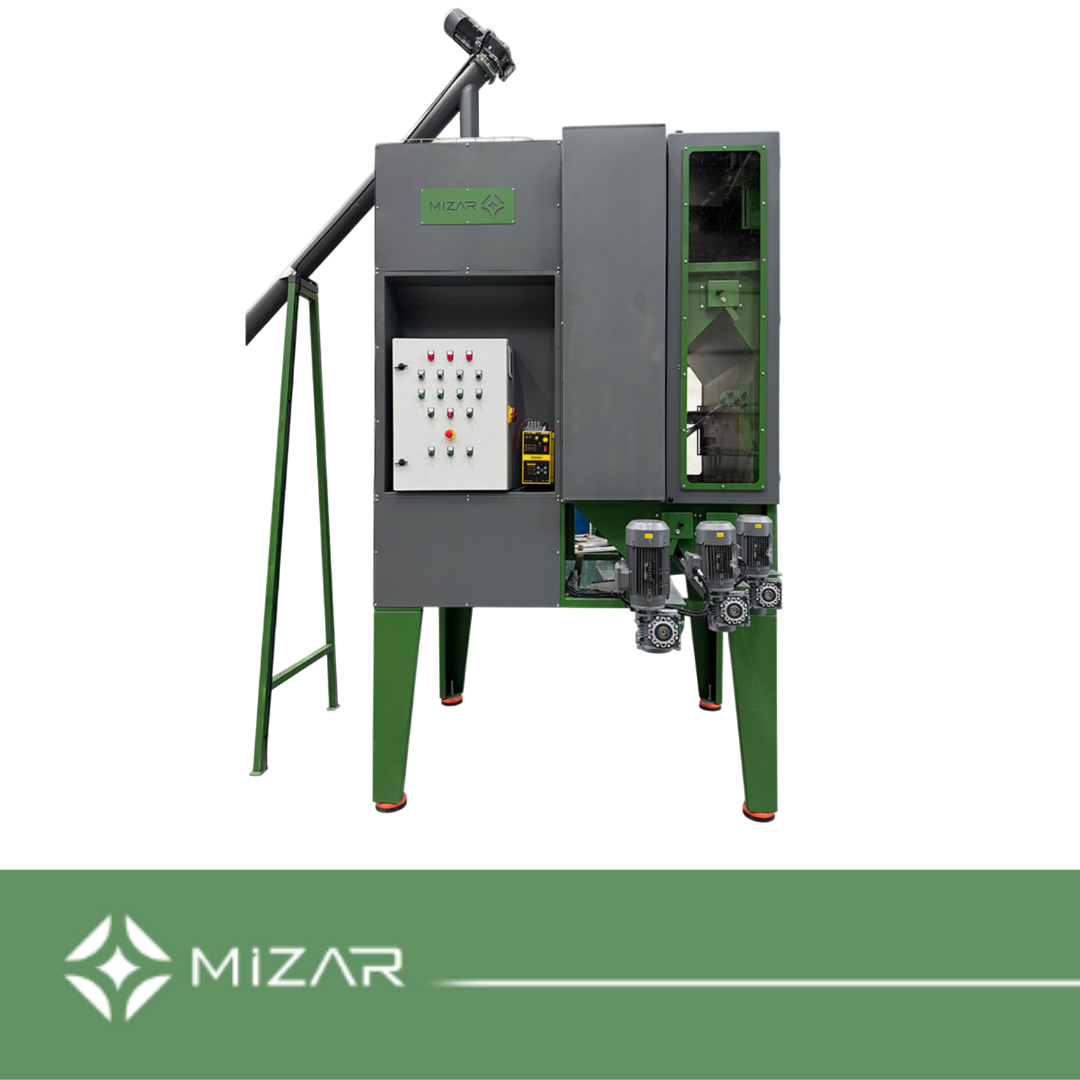

The Mizar Advantage

At Mizar, our electrostatic separators are designed with high-voltage discharge technology and fully adjustable control systems. Thanks to compact structure, easy maintenance, and plug-and-play design, our separators integrate perfectly into existing recycling lines.

Key Features:

Adjustable roller speed and voltage

High separation efficiency (>99% for copper/plastic mix)

CE-certified safety systems

Designed for continuous industrial operation

Global Trends & Data

According to recent studies, the global demand for electrostatic separators is projected to grow by 5.6% annually through 2030.

Governments across the EU now require higher recovery rates (up to 85%) for WEEE materials, making advanced separation essential.

Contact Us

+90 537 520 35 34